- Home

- »

- Projects

- »

- Labs, Audiology Rooms and Health Facilities

- »

- Vibro insulation of compressors in dental laboratory

Vibro insulation of compressors in dental laboratory

Project Overview

Dental laboratories rely on precise and stable equipment to ensure accurate work and patient comfort. At a specialised dental lab, vibration from compressors disrupted the precision of dental tasks and compromised the lab’s tranquil environment. To resolve this, DECIBEL implemented a targeted vibration insulation solution using our high-performance Vibro-EP elastic pads. This installation effectively reduced equipment vibrations safeguarded machinery, and enhanced the quality of the working environment.

Challenge

In healthcare environments such as dental laboratories, maintaining a controlled and quiet atmosphere is essential for both staff efficiency and patient comfort. The compressors in this lab generated significant vibration, which impacted not only the sensitive equipment but also created an uncomfortable work environment. DECIBEL was tasked with isolating these vibrations to ensure smooth equipment operation and optimal working conditions.

Scope of Work

- Initial Vibration Assessment: Conducted precise measurements of vibration levels to understand the frequency and amplitude of the disturbances.

- Solution Design: Designed a tailored solution using Vibro-EP elastic pads, selected based on specific vibration levels and the weight of the compressors.

- Installation: Completed installation using anti-vibration pads positioned strategically to isolate vibration at the source, ensuring stability without altering the equipment’s centre of gravity.

Solution

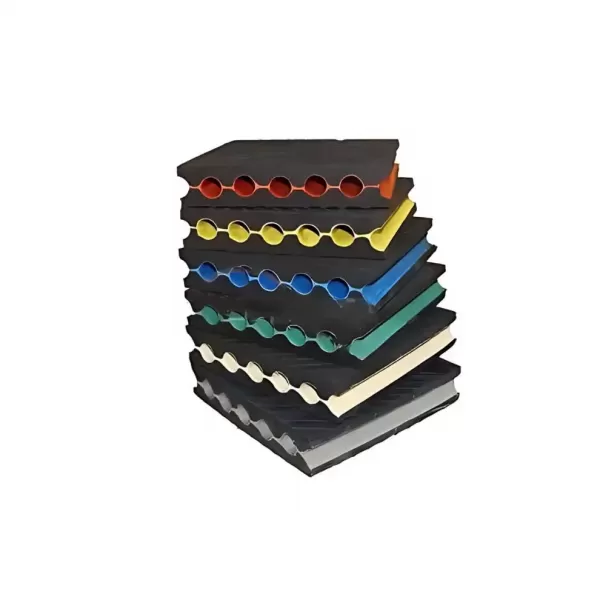

DECIBEL’s Vibro-EP anti-vibration pads were selected for their robust elasticity and enduring performance. Available in grey, blue, and red versions to suit varying weight capacities, these pads provided a balanced solution that maintained the compressors’ operational stability. The pads’ cylindrical perforations enhanced their anti-vibration properties by increasing elasticity, making them ideal for isolating vibrations effectively. For this installation, pads were strategically combined with anti-vibration springs to provide additional insulation for medium and high-frequency vibrations, ensuring comprehensive vibration management.

Result

The implementation of Vibro-EP pads immediately reduced vibrations, protecting both delicate dental equipment and lab staff from adverse effects. Noise and vibration were successfully contained, creating a stable work environment that meets the high precision standards required in dental laboratories. The result was a quieter and more focused setting, directly enhancing workflow efficiency and ensuring that dental tasks could proceed without interruption.

Importance of Vibration Control in Dental Laboratories

In healthcare and precision-focused facilities like dental laboratories, vibration control is essential to protect equipment and maintain a stable, quiet environment. Excessive vibration can interfere with the accuracy of dental work, reduce equipment lifespan, and create a stressful work environment. Proper vibration insulation, such as DECIBEL’s anti-vibration pads, not only prolongs equipment functionality but also contributes to a safe and comfortable atmosphere, benefiting both staff and patients.

DECIBEL’s anti-vibration products undergo rigorous testing to ensure compliance with healthcare standards. The Vibro-EP pads are manufactured using premium elastic materials and undergo stringent quality control, delivering reliable performance under various load conditions. With customisable options, these pads provide adaptable solutions for unique vibration challenges in healthcare and dental environments.